Since MIC Senju developed the first flux-containing solder, SPARKLE SOLDER, in Japan in 1955, we have developed a range of flux-cored wire solders for a variety of alloys and applications. For our ECO SOLDER alloy, SMIC has developed a flux-cored wire solder with improved wettability, a disadvantage inherent in lead-free solder.

ECO SOLDER NEO

Superior Wetting Properties

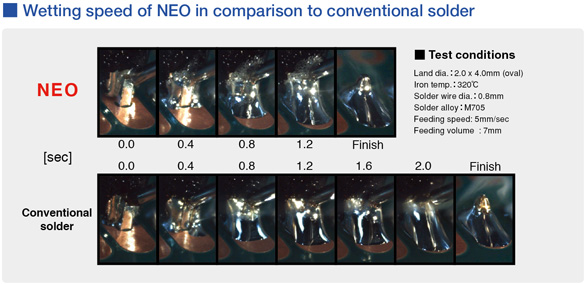

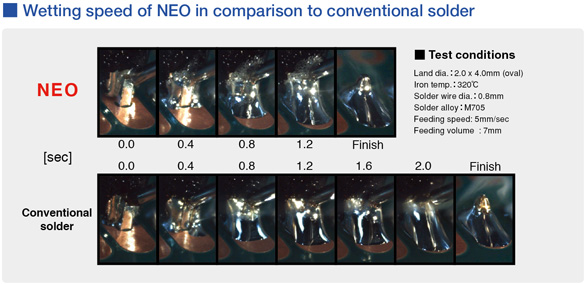

ECO SOLDER NEO further improves workability over conventional solder. This is achieved by refining the solder flux fluidity for rapid initial wetting. Low solder and flux spatter facilitate rework, while the light yellow residue contributes to a better appearance.

Below, you can see NEO's wetting speed compared to conventional solder.

ECO SOLDER NEO

High Reliability and Clean Finish

ECO SOLDER RMA08 is a reliable rosin flux-cored wire solder that complies with the former US standard QQ-S-571. It exhibits less solder spatter and has a transparent, colorless surface. It exhibits corrosion resistance and high insulation properties.

ECO SOLDER MLB

Excellent heat-resistant flux-cored wire

Newly developed heat-resistant flux-cored solder wire for PCBs exposed to high temperatures for extended periods. It achieves a clear, clean finish after soldering, providing a good appearance.

ECO SOLDER MLB

Designed for non-contact use

MLB wire offers excellent soldering properties while reducing solder spatter and contamination problems.

| |

ECO SOLDER

RMA08 |

ECO SOLDER

MLB |

ECO SOLDER

NEO |

ECO SOLDER

HVP |

| Alloy |

Please consult the ECO SOLDER product manual |

| Wire Diameter |

ø 0.3 to 2.0mm |

| Flux Content |

3%, 4% |

3%, 4% |

3%, 4% |

4% |

| Halide Content |

0.10% or less |

0.10% or less |

0.44% |

0.44% |

| Insulation Resistance |

Over ? 1 x 1011 |

Over ? 1 x 1011 |

Over ? 1 x 1011 |

Over ? 1 x 1010 |

| Spreadability |

77% (M705) |

75% (M705) |

79% (M705) |

79% (M705) |

| Features |

Clean finish and high reliability |

Non-contact Heating |

Excellent operation |

Excellent heat resistance flux |