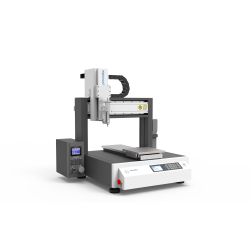

Orta ve büyük hacimli dağıtım uygulamaları için tasarlanan Helios® SD-960 Serisi, son derece aşındırıcı Termal Arayüz Malzemeleri (TIM'ler), kaplama, sızdırmazlık, contalama, yapısal yapıştırıcılar, silikonlar dahil olmak üzere çok çeşitli tek ve iki bileşenli uygulamaları destekler.

Proses gereksinimlerinizi karşılamak için Helios Serisini özelleştirin. Nordson ASYMTEK dağıtım valfleri veya tam entegre Nordson SEALANT ölçüm sistemleri ile donatılmış çift çekmeceli parti veya konveyörlü hat içi konfigürasyonlar arasından seçim yapın. Zaman-basınç valfleri, aşamalı boşluklu pompalar, kapalı döngü proses kontrolü ve servo kontrollü pozitif deplasmanlı sistemler gibi seçeneklerle sisteminizi tamamlayın.

Diğer Nordson ASYMTEK dağıtım sistemlerinde bulunan, patent bekleyen Kütle Akışı Kalibrasyonu (MFC) seçeneği, ağırlık kontrollü dağıtım ve otomatik kalibrasyon aracılığıyla dağıtım hacimlerinin tanımlanmış işlem sınırları içinde kalmasını sağlar.

Özellikler ve Seçenekler

• Entegre kontrollere sahip isteğe bağlı iki bileşenli (2K) ölçüm sistemleri

• Kullanıcı tarafından programlanabilen dağıtım geometrileri ile Fluidmove® Yazılımı

• İsteğe bağlı büyük kapasiteli tartı ile patent bekleyen MFC

• Otomatik XYZ iğne konumu telafisi için isteğe bağlı sensör

• Programlama ve referans tanıma için kamera sistemi

• Kolay temizlik için paslanmaz çelik yüzey tasarımı

• Toplu sıvı besleme hortumlarının verimli şekilde yönlendirilmesi

• Bir ve iki bileşenli TIM'leri dağıtmak için ideal

Konveyörlü Hat İçi İmalat

Entegre bir SMEMA uyumlu konveyör sistemi ile donatılmış Helios Serisi hat içi konfigürasyon ile ürünü işleme alanına otomatik olarak taşıyın.

Çift Çekmeceli Parti İmalatı

Toplu üretim sürecinizi durdurmadan aynı anda boşaltın, yükleyin ve dağıtın. Helios Serisi çift çekmece konfigürasyonu ile operatörler, sistemin ön tarafına yerleştirilmiş iki kolay erişimli çekmeceden parçaları işler. Sistem iki çekmece arasında geçiş yapar – bir çekmecedeki bir parçaya dağıtım yapar ve daha sonra otomatik olarak bitişik çekmecedeki bir parçaya dağıtım yapmak için hareket eder. Dağıtım tamamlandığında, operatör tamamlanmış parçayı ilk çekmeceden boşaltmakta ve işleme için yeni bir parçayı yeniden yüklemekte özgürdür.

Fluidmove Dağıtım Yazılımı

Spectrum®ll ve Quantum® dağıtım sistemleri gibi, Helios Serisi de, kullanıcıların standart bir Windows ortamında programlama ve dağıtım süreçlerinin kontrolünü ele geçirmelerini sağlayan Fluidmove yazılımıyla donatılmış bir dizüstü bilgisayar içerir. Sistem kamerası ve yükseklik sensörü, ek donanıma ihtiyaç duymadan dağıtım sonuçlarını kontrol etmek için dağıtım sonrası komutları destekler. Daha detaylı inceleme gerekiyorsa, platform bir denetim sistemi ile yapılandırılabilir.

Dökme Sıvı Dağıtım Sistemleri

Bir dizi uygulamayı desteklemek için Helios Serisi için çok çeşitli tek ve iki bileşenli dağıtım valfleri mevcuttur.

Sistemler, uzak toplu besleme hortumları, valfler ve karıştırıcılar için dikey boşluk sağlamak üzere gerektiğinde bir toplu akışkan hortumu muhafazası ("üst şapka") ile donatılmıştır.

Akışkan tedarik sistemleri, farklı rezervuar boyutları, akışkan regülatörleri, takviye pompaları, gaz giderme seçenekleri, seviye sensörleri ve daha fazlasıyla özel malzeme ve uygulama gereksinimleri için özelleştirilebilir.